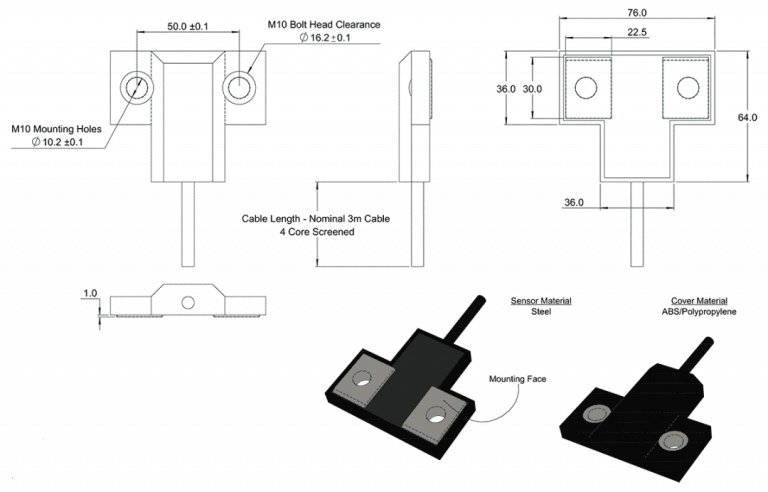

Datum 2-Hole Bolt-On Strain Gauge Sensor

Product Description

The series 460 2-hole bolt-on sensor is not only an essential product for measuring micro-straight, but it can also become an integral part of a strain monitoring system for using in harsh environments. Datum Electronics offers two types of multi-element strain gauge bolt-on strain sensors that have been developed to provide a rugged and robust production sensor with the benefits, associated with a complex strain gauge installation. Designed to measure tensile and compressive bending strains ranging from 50 to 1100 micro-strain, for use in applications including vehicles, civil engineering structures, silo, hoppers, vessels, and specialist engineering projects.

Key Features

Bolt on strain sensors are widely used, however, they are dependent on the bolting down friction. When strains exceed about 600 micro-strain and have shock loads, conventional bolt-on strain sensor will show zero shifts. The Datum design of the bolt-on strain sensors is very compliant and can be used at much larger strain up to 10,000 micro-strain. The initial application was done for forged vehicle axles, where strains exceed 1500 micro-strain and a usual bolt-on sensor had been previously dismissed.

With the latest strain gauge techniques and technologies, the bolt-on strain sensor gives you accurate and reliable data, you require in a number of challenging environments. The bolt-on sensors are fully compatible with our wide range of load and strain indicators and amplifiers, allowing you to operate any number of sensors in parallel for your application. A direct serial link to a PC, or an analogue input to a data logger or PLC, is also an option and also very easy to achieve.