Datum Advanced Engine Monitoring Datum Hawk

Product Description

What is Datum Hawk?

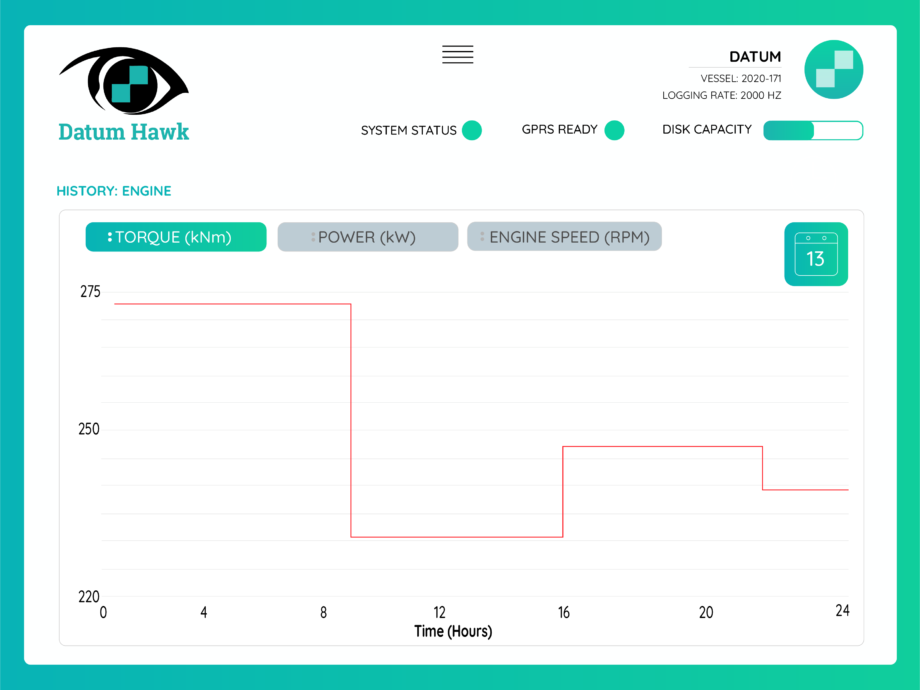

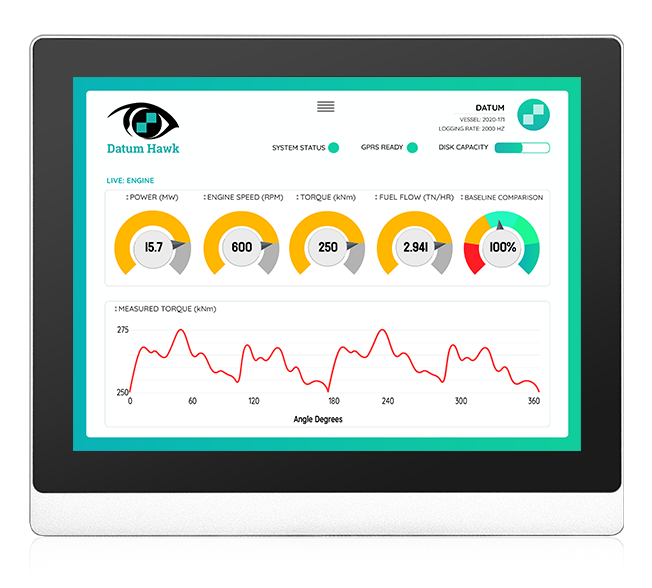

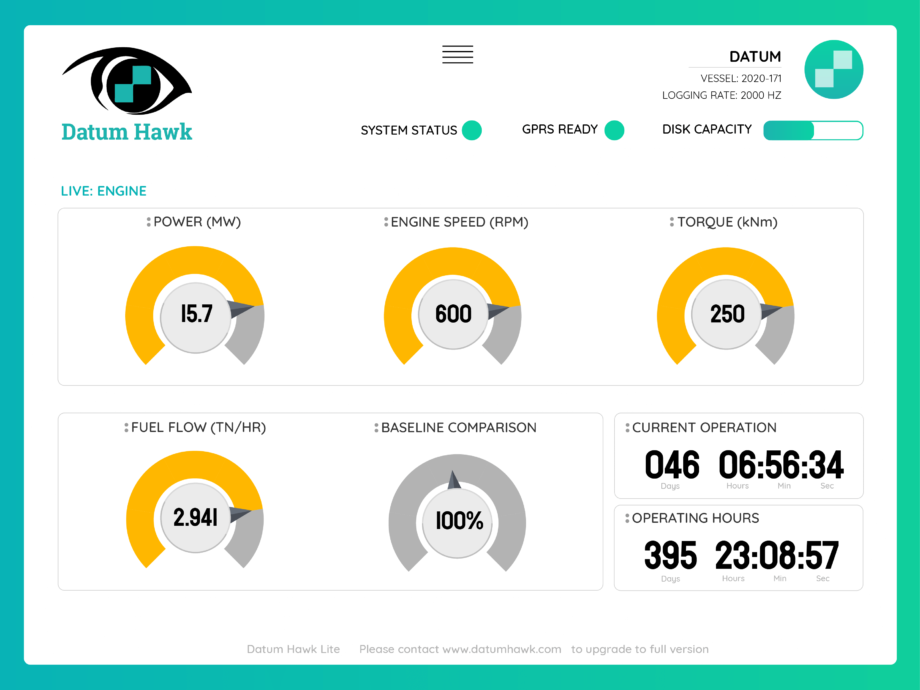

Datum Hawk is an advanced engine monitoring system utilizing industry leading contact free Shaft Power Measurement system to provide insight into the very workings of the engine. The SPM system is compact and easily retrofitted to any vessel, and the new technology within Datum Hawk will allow vessels to move to a more intelligent forms of engine monitoring and maintenance.

AI-Enabled Condition Monitoring

The Datum Hawk project, developed by Datum Electronics in partnership with Strathclyde University’s renowned Marine Engineering department, represents a change in the way that marine vessels will operate planned maintenance across engine rooms across engine rooms, helping improve vessel efficiency and optimisation.

Datum Hawk empowers engineers to adopt condition-based maintenance strategies in place of traditional fixed interval maintenance schedules using TVA (Torsional Vibration Analysis) to understand the true performance conditions of marine engines.

Marine Engine Performance Monitoring

Leveraging monitoring data produced by Datum’s new SPM (Shaft Power Measurement) system, early identification of anomalies can be flagged. This compact performance monitoring solution is easily fitted to any marine engine’s intermediate shaft, either as a new build or simple retro fit.

Easily Plan Maintenance Interventions

TVA detects subtle changes in marine engine vibration that can indicate wear, misalignment or impending failures. By continually monitoring engine performance, maintenance teams can plan timely intervention, preventing costly breakdowns and minimising downtime.

Seamless integration with flow meters extends Datum Hawk’s capabilities to include Specific Fuel Oil Consumption (SFOC) as well as integration with our EEXI / ShaPoLi monitoring system.

Attributes

- Torsional Vibrational Analysis detects subtle changes in engine vibrations that might indicate the presence of wear, misalignment, or impending failures. By identifying these issues in their early stages, maintenance teams can plan timely interventions, preventing costly breakdowns and minimizing downtime.

- With a thorough understanding of the torsional behaviour of the engine, maintenance personnel can optimize the design and selection of critical components. This optimization translates to increased component life, reducing the need for frequent replacements and enhancing the engine’s overall longevity.

- TVA empowers engineers to move away from traditional fixed-interval maintenance schedules and adopt condition-based maintenance strategies. By basing maintenance decisions on real-time data, teams can avoid unnecessary overhauls, thereby optimizing resources and costs.

- Engine failures can have disastrous consequences, especially in critical applications like aerospace and marine industries. Torsional Vibrational Analysis helps ensure the safety and reliability of engines, leading to enhanced performance and peace of mind for operators and users.

- Integration: Seamlessly integrate with our range of Coriolis Mass Flow Meters in order to manage Specific Fuel Oil Consumption (SFOC), or our EEXI / ShaPoLi monitoring system to ensure MARPOL Annex VI / MEPC.335(76) regulations.