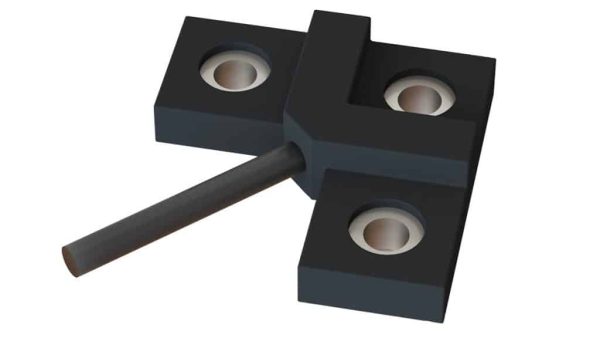

Datum Series 460 3-Hole Bolt-On Strain Gauge Sensor

Product Description

The series 460 3-hole bolt-on strain sensor has a unique design, eliminating the temperature effect on bending and strain of the application, and. can work in almost any environment and in any weather.

Datum Electronics offers two types of multi-element bolt-on strain sensor that have been developed to provide a rugged and robust production sensor with the benefits associated with a complex strain gauge installation. The bolt-on strain sensors have been designed to measure tensile and compressive bending stresses ranging from 50 to 1100 micro-strain, for use in applications including vehicles, civil engineering structures, silos, hoppers, vessels, and specialist engineering projects

High Strain Bolt-On Sensors

Bolt on strain sensors are widely used, however, they are dependent on the bolting down friction. When strains exceed about 600 micro-strain and have shock loads conventional bolt-on strain sensor will show zero shifts. The design is very compliant and can be sued at much larger strain up to 10,000 micro-strain. The initial application was for forged vehicle axles where strains exceed 1500 micro-strain and the idea of a bolt-on sensor had been previously dismissed.

Bolt-On Strain Gauge Sensors Specification

Strain Gauge Bolt-on Strain Gauge Weight Sensors are quick and easy to install without any fine wiring or soldering. Its practical robust design allows the strain sensor to work in almost any environment, in any weather and even underwater if required. Rated to IP68, this is a truly universal product that will give you reliable accurate strain indication, whatever the application or environmental condition. All sensors are pre-tested and checked during final assembly, ensuring the reliability and quality of all our sensors.

- Rated Strain Range: 10 – 1,100 micro-strain

- Rated Output: 1.5mV/V for 1,000 micro-strain (nominal)

- Repeatability: 0.1% FSD

- Environmental Protection: IP68

- Operating Temperature: -20ºC to +80ºC

Raw Strain Gauge Bridge Output – the bolt-on sensor has a four wire connection to the strain gauges that are configured as a Wheatstone bridge. This output will require an amplifier. It will be compatible with most strain gauge amplifiers and indicators.

-

4-20mA outputs:

– 4mA = 600 micro-strain, 12mA zero, 20 mA = +600 micro-strain

– 4mA = {customer value} micro-strain, 12mA zero, 20 mA = {customer value} micro-strain

– 4mA = Zero, 20mA = 1000 micro-strain

– 4mA = Zero, 20mA = {customer value}

Note when selecting your output value please allow for the sensor to show up to a 200 micro-strain offset when bolted to surface that is not flat. Even with ground flat surfaces a small offset will occur -

0-10Vdc outputs:

– 0V = 600 micro-strain, 5V zero, 20 mA = 10V micro-strain

– 0V = {customer value} micro-strain, 5V zero, 10V = {customer value} micro-strain

– 0V = Zero, 10V = 1000 micro-strain

– 0V = Zero, 10V = {customer value}

Note when selecting your output value please allow for the sensor to show up to a 200 micro-strain offset when bolted to surface that is not flat. Even with ground flat surfaces a small offset will occur. -

Serial RS485 Output

-

CAN Bus Output

-

PWM Output

Diversity of Bolt-On Strain Gauge Sensors

Using the latest strain gauge techniques and technologies, the bolt-on strain sensor gives you accurate and reliable data, you require in a number of challenging environments. The bolt-on sensors are fully compatible with our wide range of load and strain indicators and amplifiers, allowing you to operate any number of sensors in parallel for your application. A direct serial link to a PC, or an analogue input to a data logger or PLC, is another option.