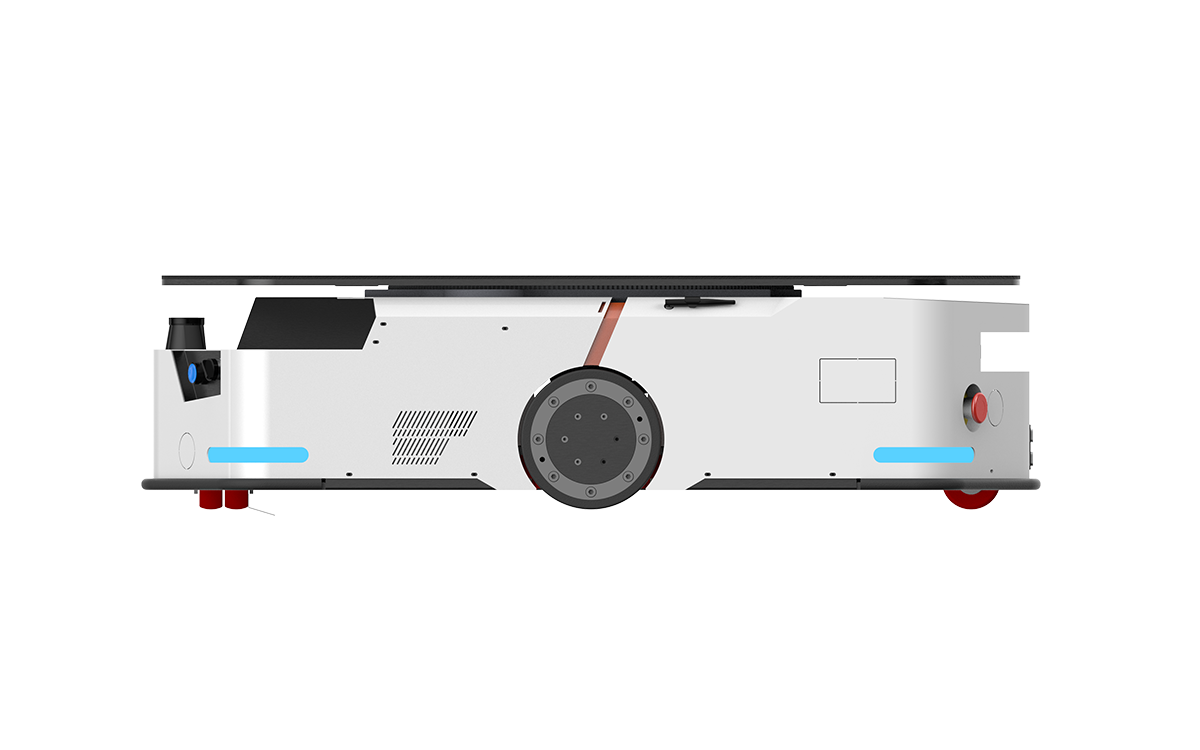

YouIBot L300 /L1000 Lifting series robot

Product Description

Model L300

- Easily automate intralogistics for narrow manufacturing spaces with cost-effective solution.

- Lifting module raises trolleys, pallets, shelves, and more.

- Secure autonomous navigation for safe and effective transport.

- Meets industry compliance standards.

- 300 KG Lifting Payload capacity

- 8H Run Time

- 800mm x 619mm x 330mm

- SLAM/QR Code Navigation Knowledge

Compact but Agile AMR

The L300 is a Autonomous Mobile Robot designed to improve internal transportation efficiency in the manufacturing industry. The agile body is equipped with a high capacity 30Ah battery, providing at least 8 hours of uninterrupted operation. This allows for production schedules to be met between shift changes, resulting in virtually uninterrupted production and increased productivity. With the L300, companies can move towards achieving Industry 4.0 and reap the benefits of advanced automation technology.

Flexible Deployment for Quick Start-up

With a highly integrated control system featuring proprietary functionality, the L300 is a top-of-the-line robot. It achieves a high level of accuracy of ±10mm using only SLAM navigation and ±5mm when combining SLAM and QR navigation. The intelligent control system can also correct for small derailments, while the BMS battery control system enables real-time monitoring of the battery level and automatic charging when necessary. The L300 is a reliable and efficient solution for material handling in manufacturing.

Powerful Rotating Lifting Module

The L300 drive chassis remains the same size even with the integration of the rotary lifting module. The module can handle loads up to 300KG and is calibrated for optimal performance. The integrated control system features a lifting platform posture-follow function, enabling smooth turns and precise placement in tight spaces while maintaining carrier orientation and posture. The module also features a simple and reliable pin design to ensure load stability and prevent falls, as well as a rubber pad on the upper layer to reduce vibration and minimize material damage during handling.

Features

- Full enclosure security enables real-time human-robot collaboration.

- Custom audio and lighting for various scenarios with notifications.

- Humane emergency stop design and safety bumpers ensure safety in urgent situations.

- Concealed debugging panel improves quick troubleshooting convenience.

- Stable center of gravity guarantees the safety of the goods during transportation.

Model L1000

- The most powerful AMRs automate the movement of goods, racks and pallets for heavy workload handling in internal transportation.

- Efficiently navigates dynamic environments with ease

- cost-effective AMRs meet industry safety standards

- Fast Return on Investment

- 1000 KG Lifting Payload Capacity

- 8H Run Time

- SLAM/QR Code Navigation Knowledge

High payload AMR

The L1000 is a Autonomous Mobile Robot with a high payload capacity designed to enhance material handling efficiency in manufacturing. It features a 48Ah battery and a rotary lifting module capable of lifting loads of up to 1000kg. With the ability to operate for 8 hours while handling heavy loads, the L1000 boosts productivity and facilitates Industry 4.0 implementation.

Flexible deployment for quick start-up

With a highly integrated control system featuring proprietary functionality, the L1000 is a top-of-the-line robot. It can achieve a high level of accuracy of ±10mm using only SLAM navigation and ±5mm when combining SLAM and QR navigation. The intelligent control system can also correct for small derailments, while the BMS battery control system enables real-time monitoring of the battery level and automatic charging when necessary. The L1000 is a reliable and efficient solution for material handling in manufacturing.

Compact but powerful rotating lifting module

The L1000 drive chassis remains the same size even with the integration of the rotary lifting module. The module can handle loads up to 1000KG and is calibrated for optimal performance. The integrated control system features a lifting platform posture-follow function, enabling smooth turns and precise placement in tight spaces while maintaining carrier orientation and posture. The module also features a simple and reliable pin design to ensure load stability and prevent falls, as well as a rubber pad on the upper layer to reduce vibration and minimize material damage during handling.

Features

- Full enclosure security enables real-time human-robot collaboration

- Custom audio and lighting for various scenarios with notifications

- Humane emergency stop design and safety bumpers ensure safety in urgent situations.

- Concealed debugging panel improves quick troubleshooting convenience.

- The stable center of gravity design guarantees the safety of the goods during transportation.